|

Database of Waste Management Technologies |

|

Case Study 6 - Composting

| General Information | Photo Gallery | |

|---|---|---|

| Name: | Biowaste Composting Facility in Cloppenburg-Stapelfeld |

Biowaste Composting Facility in Cloppenburg-Stapelfeld |

| Owner: | - | |

| Operator: | Nehlsen GmbH & Co. KG Niederlassung Nord-West 26434 Wangerland | |

| Technology: | Composting in boxes (Herhof-Boxes) | |

| Designed Capacity: | 20,000 tpa | |

| Cost: | n/a | |

| Location: | Cloppenburg-Stapelfeld, Germany | |

| Served Area: | Cloppenburg district | |

| Commercial Start Up: | 1994 | |

| Contact Details | ||

| Address: | Henkingsweg 49661 Cloppenburg Germany |

|

| Phone Number: | +49 044 71 94 76 60 | |

| Fax: | + 49 044 71 94 76 61 | |

| Email: | ka-cloppenburg@biokomp.de | |

| Website: | - | |

Short Description

The biowaste composting facility in Cloppenburg-Stapelfeld, Germany, is part of the central waste disposal area of Cloppenburg district. The nearest residential area is about 0.5 km away.

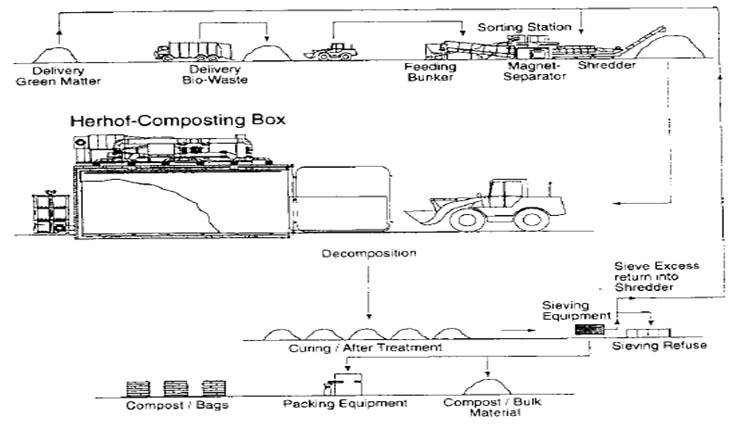

The facility processes source separated biowaste from households, yard waste from residential, institutional and commercial sources and potato processing waste. It is in operation since July 1994, has a current capacity of 20,000 tpa and employes 3,5-4 people. Composting is carried out in 12 boxes (Herhof Composting boxes), each with a volume of 50 m3. Further equipment includes 2 front-end loaders, 1 trommel screen, 1 self-built air classifier, 1 hammermill, 1 overhead magnet, 1 handsorting room, 2 biofilter boxes ( 50 m3 each) various belt conveyors. Temperature in the off-gases are initially controlled at 45 oC for optimum degradation and then at 60 oC for 3 days for pathogen control. A composting box is devided into six different aeration segments and has 1 blower for fresh air and 1 blower for the off-gas and air recirculation. Leachate is recirculated to keep the moisture content of the biowaste at 50% by weight and to avoid discharging highly contaminated water into the sewer at high costs. The retention time in composting boxes are 6-7days plus 2 weeks in windrows (end-product is fresh compost) or 10-12 weeks in windrows (end product is a mature compost)

Key Facts

| Treatment Capacity: | 20,000 tpa | |

|---|---|---|

| Input Material: | Source separated biowaste | 20,000 tpa |

| Yard waste | ||

| Potato processing waste | ||

| Output Products: | Compost | - |

Extra Information

Display of biowaste decomposition with the Herhof box system.