|

Database of Waste Management Technologies |

|

Case Study 11 - Waste to Energy (WtE)

| General Information | Photo Gallery | |

|---|---|---|

| Name: | Torsvik CHP Plant, Sweden |

The Torsvik CHP plant in Sweden |

| Owner: | Municipality of Jönköping | |

| Operator: | Jönköping Energi AB | |

| Technology: | WtE-CHP | |

| Designed Capacity: | 162,000 tpa | |

| Cost: | n/a | |

| Location: | Munksjö paper mill, Torsvik, Sweden | |

| Served Area: | Jönköping Municipality | |

| Commercial Start Up: | 2006 | |

| Contact Details | ||

| Address: | Jönköping Energi AB, Kjellbergsgatan 3, box 5150, 550 05 Jönköping |

|

| Phone Number: | +46 03610 82 00 | |

| Fax: | +46 03616 68 85 | |

| Email: | ||

| Website: | www.jonkopingenergi.se | |

Short Description

The Torsvik combined heat and power (CHP) plant, developed by Jönköping Energi AB, was put into operation in 2006. The plant uses a grate type boiler to combust 162,000 tonnes per year.

Torsvik is designed to produce 350 GWh of heat and 100 GWh of electricity annually, with an overall plant efficiency of 92% and in conformity with the Waste Frame Directive energy efficiency criteria. The heat is delivered to the district heating network in Jönköping and Huskvarna, which supplies around 30,000 households and municipal localities in these communities. The Torsvik plant covers half of this demand. Electricity produced is fed to the grid.

The municipal waste burned at the plant can be sorted or mixed combustible waste depending on the community where it originates. In Jönköping, source sorting is gradually being implemented and food waste is separated from other combustible waste. The food waste is converted to biogas and bio-fertilizer. The biogas is used in vehicles while the bio-fertilizer replaces synthetic fertilizer.

Waste fuel delivered to the Torsvik plant is dumped in a 17,000 m3 bunker. The fuel is a mix of 40% municipal solid waste and 60% industrial waste, with an average heating value of 11.7 MJ/kg.

Key Facts

| Treatment Capacity: | 162,000 tpa | |

|---|---|---|

| Input Material: | MSW 40% - Industrial Waste 60% | 162,000 tpa |

| Output Products: | Electricity | 350 GWh pa |

| Heat | 100 GWh pa |

Extra Information

Torsvik process flow chart

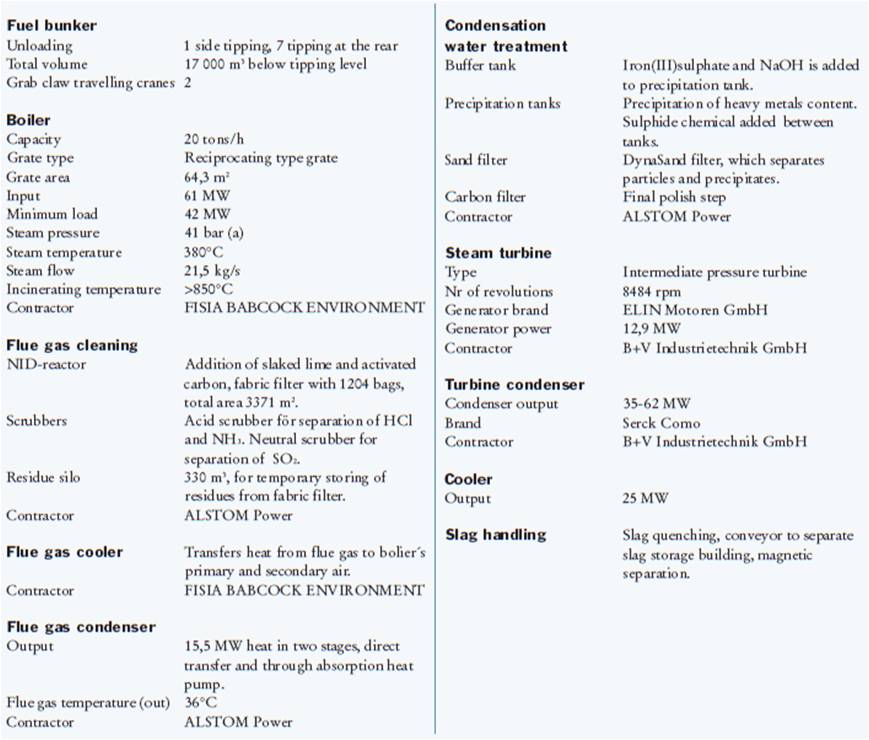

Technical facts of the respective process parts of the Torsvik CHP plant in Sweden