|

Database of Waste Management Technologies |

|

Case Study 18 – MBT with hand-picking & open windrow composting

| General Information | Photo Gallery | |

|---|---|---|

| Name: | 15th May Compost Plant |

15th May Compost Plant [Environics & ERACU, 2007, Environmental Management for 15th of May Compost Plant (Report), Cairo]

Open windrows at the 15th May Compost Plant [Environics & ERACU, 2007, Environmental Management for 15th of May Compost Plant (Report), Cairo]

Mobile screening unit used at the 15th May Compost Plant [Environics & ERACU, 2007, Environmental Management for 15th of May Compost Plant (Report), Cairo]

Aerophotograph-15th May Compost Plant [Environics & ERACU, 2007, Environmental Management for 15th of May Compost Plant (Report), Cairo] |

| Owner: | Egyptian government [Constructed and supplied by NOMP (National Organization of Military Production] | |

| Operator: | Egyptian Company for Solid Waste Recycling (ECARU) | |

| Technology: | Composting (Open air windrows) | |

| Designed Capacity: | 1,500 tpa | |

| Cost: | n/a | |

| Location: | 15th May, Cairo | |

| Served Area: | South Cairo Zone | |

| Commercial Start Up: | 2000 | |

| Contact Details | ||

| Address: | Industrial zone, Block No. 12013, District No. 5, St. 110. Obour, Egypt |

|

| Phone Number: | +20 246650961/2 | |

| Fax: | +20 246650965 | |

| Email: | - | |

| Website: | www.entag.net | |

Short Description

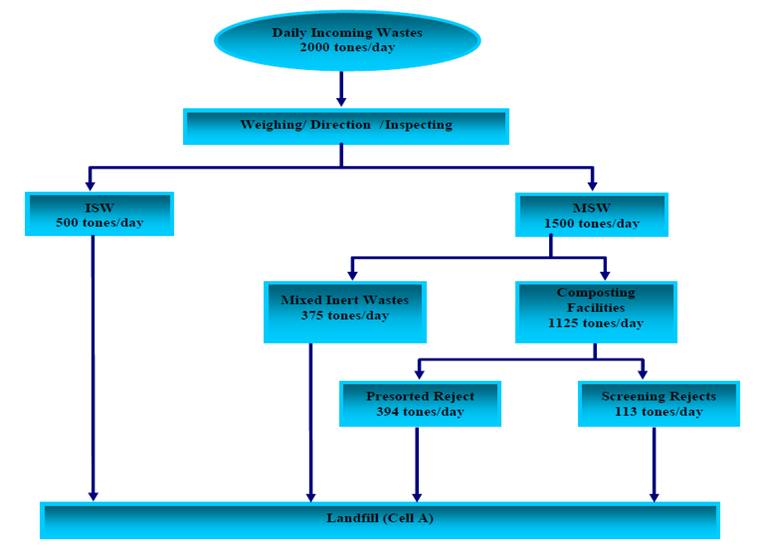

The “15th May Compost Plant” is a Composting Facility in Cairo. The facility is an integrated component of a project aiming at the management of 2,000 tons of solid waste per day. Of this amount, approximately 1,500 tons/day, comprising commingled residential and commercial waste materials, are directed to the composting facility for processing and recycling. Only rejects or overflows (35%) of the composting facility are directed to the neighboring landfill. The remaining amount, 500 tons/day, comprise inert industrial and demolition wastes that are directly conveyed for disposal. Neither the composting facility nor the landfill accept any hazardous, liquid, medical, chemical, flammable, explosive or radioactive wastes.

The current site is adjacent to the landfill and far from urban populations and from surface water resources. The site is bounded by relatively large, vacant areas of land to the North, South and East, and by the landfill to the West. The closest activities, aside of the landfill, include El-Koumia Cement company about 500 m to the south and a Cement and Brick production facilities beyond the Autostrad highway.

The 15th of May composting facility utilizes the windrow composting technology and includes two composting plants, one with a capacity 960 tons/day and the other at capacity of 640 tons/day, with a total capacity of 1,600 tons/day.

The composting process includes the following phases:

- Waste Receiving;

- Presorting of waste is carried out by four sorting laborers

in order to remove the bulk materials, including :

- Rubber tires

- Batteries

- Large textile such as carpets, blankets, etc

- Cardboard sheets and boxes, which are baled.

- Agricultural residues to be milled in a hammer mill

- Presorting of waste is carried out by four sorting laborers

in order to remove the bulk materials, including :

- Sorting of Recyclables;

- The waste is then transferred to the sorting conveyors.

- Each conveyor includes 8 stations for the recyclables that are

manually sorted. Each station is specialized in sorting and removing

one of the following materials:

- Plastic bags (two stations)

- H.D. plastic bottles

- PET bottles

- Textiles

- Paper and cardboard

- Glass

- Iron and metals

- A magnetic belt is installed before the last station to remove steel objects.

- Each type of recyclables is collected and transferred by crossrecyclable conveyors to collecting rooms.

- Aluminum and steel objects are transferred to a collecting bin, and baled by a special hydraulic baler.

- Rejects are separated from the material by fixed Trommel screen and collected by reject collecting conveyor.

- Baling of Non-organic Recyclables;

- Different recyclables are baled

-

- The organic matter is collected from trommel screens by collecting a conveyor where post-sorting of glass and any other non-organic matter is performed. The material is then transferred by an inclined conveyor to the distributing conveyor to feed dump truck to be transferred to the windrows area.

- Water is added while turning the windrows to keep the humidity always at 60%, a level which speeds up the digestion and maturation.

- The windrows are turned twice a week by special turning machines to provide the oxygen necessary for the digestion process, as well as to mill and increase the homogeneity of the residues to expand area exposed to microbe digestion.

- Preparation of the Final Product.

- Skid steer loaders feed compost to the screening units where compost is screened to less than 10 mm.

- Fine compost is packed in sacks or sold as bulky.

- The part of over size refuse is added once more to the windrows as it works as an initiator and activator to the compost and the remaining is transferred to the landfill.

- The periodic analysis is run during to the fermentation and maturation phases to ensure the quality of the compost.

- The remaining reject is transferred to the landfill.

The facility workforce is composed of 220 persons. Of these, 175 are resident at the facility, where suitable accommodation and meals are provided. The site also includes recreational spaces such as a football field.

Key Facts

| Treatment Capacity: | 1,500 tpa | |

|---|---|---|

| Input Material: | MSW | 1,500 tpd |

| Output Products: | Compost | 618 tpd |

| Mixed Inert Wastes | 375 tpd | |

| RDF | 507 tpd |

Extra Information

Waste quantity and composition scheme under normal operation conditions